Polyethylene (PE) piping for water supply

Huaxi Village brand polyethylene (PE) pipes are imported or domestic special materials for high-density polyethylene pipes, produced according to the national standard "GB/T13663.2-2018", with high strength, hygiene, non-toxicity, impact resistance, aging resistance, resistance Corrosion, light weight, easy installation and other advantages. It is widely used in many fields, because it will not rust, so it is an ideal pipe material to replace ordinary iron water supply pipes.

Polyethylene (PE) pipe for gas

Huaxi Village brand PE gas pipeline, the product quality fully meets the national GB15558.1-2015 (buried polyethylene pipe for gas) requirements. The production process strictly implements the ISO9001 and IS014001 guarantee systems. Under the specified conditions of use (refer to CJJ63-2018), its service life can reach 50 years. Perfect quality assurance system, advanced testing methods and strict testing system ensure the excellent quality of the company's products. Over the years, the company's pipe pass rate is 100%, and the factory pass rate is 100%.

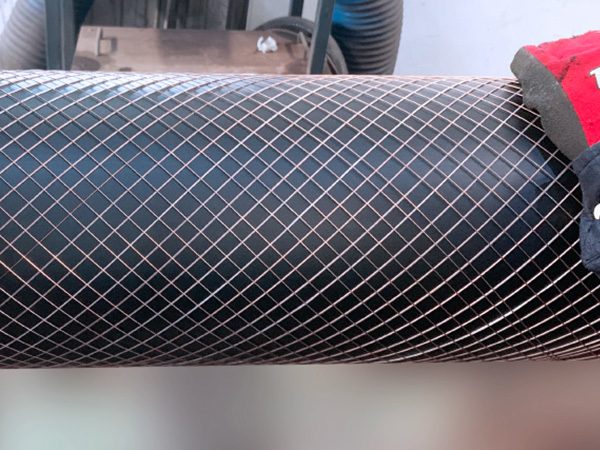

Steel mesh skeleton plastic (polyethylene) composite pipe

In the past 20 years, new plastic pipes have been widely used in municipal, gas, power plant water intake and other fields. Especially with the continuous optimization and innovation of polyethylene polymerization technology, polyethylene materials with higher and higher tensile strength have emerged. The range of pressure grades used for plastic pipes has been expanded, especially in recent years, through the research of interdisciplinary technology, the introduction of steel-plastic composite technology has satisfactorily solved the problems of polyethylene (PE) pipes in terms of pressure grades, anti-corrosion, and effective flow caliber. , for a wider range of fluid conveying applications. Structure: This product uses the core layer of the coated high-strength steel wire as the reinforced skeleton, and uses special hot-melt adhesive and plastic to form a pipe by extrusion molding.

Polyethylene (PE pipe) for trenchless drainage

Polyethylene (PE) pipes for drainage are mainly made of high-density polyethylene (HDPE) resins, which are added with necessary antioxidants, UV stabilizers, colorants, and in order to improve the processing performance of pipes and resistance to slow crack growth, etc. Performance of a small amount of other materials. The pipe has good weldability, environmental stress crack resistance and rapid crack resistance, and has been widely used in trenchless pipe jacking, lining pipe, traction pipe and other projects.

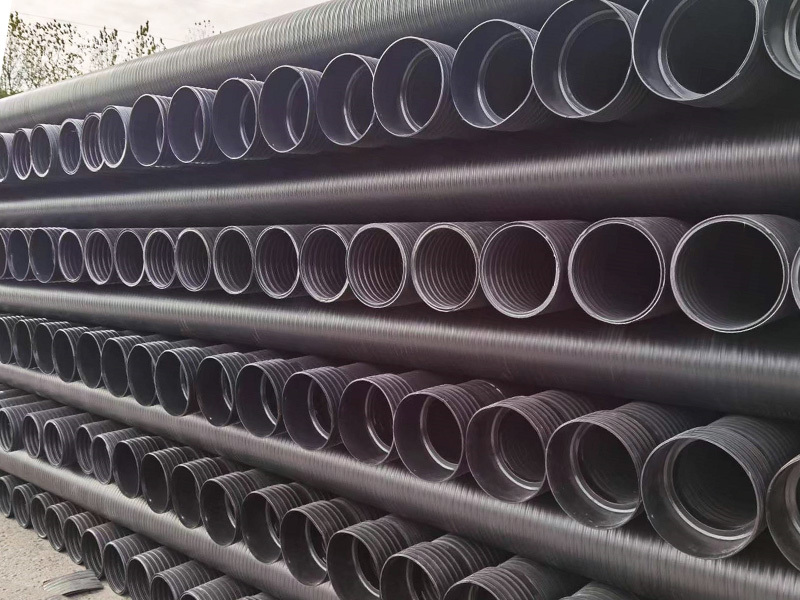

High Density Polyethylene (HDPE) Double Wall Corrugated Pipe

HDPE double-wall corrugated pipe is a new type of pipe with annular structure outer wall and smooth inner wall. It was first successfully developed in Germany in the early 1980s. After more than ten years of development and improvement, it has developed from a single variety to a complete product series. It is very mature in production process and use technology. And in accordance with GB/T 19472.1-2019 "Buried Polyethylene (PE) Structural Wall Piping System" Part 1: "Polyethylene Double Wall Corrugated Pipe".

Buried polyethylene (HDPE) hollow wall wound pipe

HDPE hollow wall winding pipe is a kind of structural wall pipe made of high density polyethylene (HDPE) by winding molding process. The implementation standard is based on GB/T19472.2 2017 "Buried Polyethylene (PE) Structural Wall Piping System" Part II: "Polyethylene Winding Structural Wall Pipe", this pipe is suitable for municipal water transport temperature below 45"C Drainage, building outdoor drainage, buried farmland transportation and drainage, industrial sewage, road drainage, sewage treatment plants, sports ground plaza engineering drainage and electrical and telecommunication engineering, etc. Because the HDPE hollow wall winding pipe is a chemical building material. Protecting the environment is of great significance.

Buried polyethylene (HDPE) hollow wall wound pipe

HDPE hollow wall winding pipe is a kind of structural wall pipe made of high density polyethylene (HDPE) by winding molding process. The implementation standard is based on GB/T19472.2 2017 "Buried Polyethylene (PE) Structural Wall Piping System" Part II: "Polyethylene Winding Structural Wall Pipe", this pipe is suitable for municipal water transport temperature below 45"C Drainage, building outdoor drainage, buried farmland transportation and drainage, industrial sewage, road drainage, sewage treatment plants, sports ground plaza engineering drainage and electrical and telecommunication engineering, etc. Because the HDPE hollow wall winding pipe is a chemical building material. Protecting the environment is of great significance.

Buried polyethylene (HDPE) hollow wall wound pipe

HDPE hollow wall winding pipe is a kind of structural wall pipe made of high density polyethylene (HDPE) by winding molding process. The implementation standard is based on GB/T19472.2 2017 "Buried Polyethylene (PE) Structural Wall Piping System" Part II: "Polyethylene Winding Structural Wall Pipe", this pipe is suitable for municipal water transport temperature below 45"C Drainage, building outdoor drainage, buried farmland transportation and drainage, industrial sewage, road drainage, sewage treatment plants, sports ground plaza engineering drainage and electrical and telecommunication engineering, etc. Because the HDPE hollow wall winding pipe is a chemical building material. Protecting the environment is of great significance.

MPP modified polypropylene power cable sheath is a solid-walled pipe with smooth inner and outer walls, which is extruded from modified polypropylene PP. The pipe has excellent electrical insulation, light weight and environmental protection, not easy to age, high temperature resistance, resistance to external pressure, high axial strength and excellent ductility and flexibility. It can destroy the surface without a lot of digging and dredging. , riverbed and other special areas for laying power cables. The pipe material can meet the needs of the sheath pipe material for high-voltage power transmission cables above 10KV.

MPP modified polypropylene power cable sheath is a solid-walled pipe with smooth inner and outer walls, which is extruded from modified polypropylene PP. The pipe has excellent electrical insulation, light weight and environmental protection, not easy to age, high temperature resistance, resistance to external pressure, high axial strength and excellent ductility and flexibility. It can destroy the surface without a lot of digging and dredging. , riverbed and other special areas for laying power cables. The pipe material can meet the needs of the sheath pipe material for high-voltage power transmission cables above 10KV.

MPP modified polypropylene power cable sheath is a solid-walled pipe with smooth inner and outer walls, which is extruded from modified polypropylene PP. The pipe has excellent electrical insulation, light weight and environmental protection, not easy to age, high temperature resistance, resistance to external pressure, high axial strength and excellent ductility and flexibility. It can destroy the surface without a lot of digging and dredging. , riverbed and other special areas for laying power cables. The pipe material can meet the needs of the sheath pipe material for high-voltage power transmission cables above 10KV.

New Zealand Farmland Irrigation Project

Ouradvantages公司简介江苏华塑新型建材有限公司投资组建于2007年,是华西村集团旗下一家大型PE管道生产、研发与销售企业。公司引进许多国际先进的生产设备与技术,结合华西集团多年严格的品质管理经验,具有华东地区一定规模的产品生产和技术开发能力。目前,公司拥有先进的生产线二十余台,各类设备与检测仪器100余台;下属有广州、深圳、上海等多家分公司,并拥有强大的销售力量和完善的服务体系,在国内

Qinghai Province Golmud Chengdong Sewage Treatment Plant

Ouradvantages公司简介江苏华塑新型建材有限公司投资组建于2007年,是华西村集团旗下一家大型PE管道生产、研发与销售企业。公司引进许多国际先进的生产设备与技术,结合华西集团多年严格的品质管理经验,具有华东地区一定规模的产品生产和技术开发能力。目前,公司拥有先进的生产线二十余台,各类设备与检测仪器100余台;下属有广州、深圳、上海等多家分公司,并拥有强大的销售力量和完善的服务体系,在国内